Introduction to DEKRA VT1000 Pitting Images

When it comes to vehicle inspections, details matter. Enter the DEKRA VT1000 pitting images—an innovative tool that revolutionizes how we evaluate a vehicle’s condition. Imagine having the power to spot potential issues before they become major headaches. With technology like this, inspectors can enhance their accuracy and efficiency, ensuring safety on the road is never compromised.

But what exactly are these pitting images? Why should they be at the forefront of every inspection process? In this post, we’ll dive into the significance of DEKRA VT1000 pitting images and explore how they help keep vehicles in top shape while safeguarding drivers and passengers alike. Whether you’re an industry professional or just curious about automotive care, you’ll discover why these images are becoming indispensable in today’s inspection landscape.

Importance of Inspections and Identifying Vehicle Pitting

Regular inspections are essential for vehicle maintenance and safety. They help identify potential issues before they escalate into costly repairs or dangerous situations. One critical aspect of these inspections is identifying pitting, small corrosion-like defects that can compromise a vehicle’s integrity.

Pitting often occurs in vital areas like the chassis and suspension components. It can lead to structural weakness, affecting performance and safety during operation. Detecting these imperfections early allows owners to address them promptly.

Ignoring signs of pitting could result in severe repercussions down the line, including diminished resale value and increased risk on the road. The importance of thorough inspections cannot be understated; they serve as a preventative measure against unforeseen breakdowns. Ensuring that your vehicle is free from pitting contributes significantly to its longevity and reliability, ultimately enhancing your driving experience.

Understanding the DEKRA VT1000 Pitting Images Technology

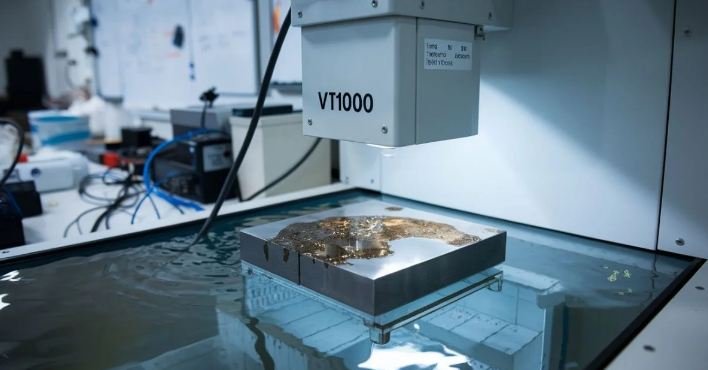

The DEKRA VT1000 Pitting Images technology represents a significant advancement in vehicle inspection processes. This innovative system captures detailed images of the surface condition of vehicles, focusing specifically on pitting—an issue that can indicate deeper structural problems.

Using high-resolution imaging, the VT1000 highlights imperfections and irregularities that may otherwise go unnoticed during standard inspections. The clarity of these images allows inspectors to assess potential risks accurately and efficiently.

Moreover, this technology integrates advanced algorithms to analyze patterns in the data collected. It provides insights into wear levels and helps predict future maintenance needs.

By leveraging such sophisticated tools, automotive professionals can enhance their inspection capabilities significantly while ensuring higher safety standards for drivers on the road. The precision offered by DEKRA VT1000 pitting images truly transforms how we understand vehicle integrity.

Benefits of Using DEKRA VT1000 Pitting Images in Inspections

Utilizing DEKRA VT1000 pitting images during inspections offers numerous advantages. These high-resolution visuals capture the intricate details of surface conditions, making it easier to identify potential problems.

Inspectors can quickly assess the severity of wear or damage. This proactive approach helps in addressing issues before they escalate into significant safety hazards.

The technology enhances communication among team members and clients. Detailed imagery provides a clear reference point for discussions about vehicle health and necessary repairs.

Moreover, using pitting images streamlines the inspection process. Inspectors spend less time on subjective evaluations and more on accurate diagnostics.

This precision also contributes to better compliance with regulations, ensuring vehicles meet safety standards efficiently. With DEKRA VT1000 pitting images, inspections become not only more reliable but also faster, ultimately benefiting both service providers and vehicle owners alike.

Case Studies: Real-life Examples of How DEKRA VT1000 Pitting Images Helped Identify Potential Issues

In a notable case, a fleet management company used DEKRA VT1000 pitting images to assess their trucks. The technology revealed subtle surface imperfections that were missed during routine inspections. These findings allowed the company to address potential failures before they escalated into costly repairs.

Another instance involved an automotive manufacturer discovering pitting in critical components on their assembly line. By utilizing these advanced imaging techniques, engineers pinpointed areas needing attention immediately, ensuring product safety and quality.

A small repair shop also benefited from this innovative tool. They were able to provide customers with clear visual evidence of wear and tear on vehicles, improving transparency in service recommendations. This not only built trust but also increased customer satisfaction.

These real-world applications demonstrate how DEKRA VT1000 pitting images are transforming inspection processes across various sectors by identifying issues early and preventing larger problems down the line.

Tips for Interpreting and Utilizing Pitting Images in Inspections

Interpreting DEKRA VT1000 pitting images requires a keen eye and an understanding of the context. Start by familiarizing yourself with common pitting patterns. Recognize what normal wear looks like compared to potential red flags.

When analyzing the images, pay attention to the depth and distribution of pits. Is there a pattern? Are they concentrated in one area or spread out? This can indicate specific issues that need further investigation.

Utilize advanced software tools that accompany the VT1000 for enhanced analysis. These can help highlight critical areas and improve accuracy in your assessments.

Engage in regular training sessions to keep your skills sharp. The more you practice interpreting these images, the better equipped you’ll be during inspections. Sharing insights with colleagues can also foster collaborative learning and improve overall inspection quality.

Always document findings meticulously for future reference, creating a reliable resource for ongoing evaluations.

Conclusion

The DEKRA VT1000 pitting images represent a significant advancement in vehicle inspection technology. They provide clear, detailed insights that play a crucial role in identifying pitting and other potential issues. These high-resolution images not only enhance inspectors’ understanding of the vehicle’s condition but also promote safety on the roads.

With their ability to reveal hidden problems, DEKRA VT1000 pitting images help prevent costly repairs down the line. The case studies discussed demonstrate how effectively these images have been used to spot vulnerabilities that might otherwise go unnoticed.

Interpreting and utilizing these pitting images can elevate the quality of inspections significantly. By harnessing this technology, industry professionals can ensure vehicles are safe for drivers and passengers alike.

Investing in advanced tools like DEKRA VT1000 is more than just keeping up with trends; it’s about fostering an environment where safety takes precedence. Adopting such innovative approaches leads to better service delivery and enhances customer trust in automotive care services.